Common types of coupling Student Lesson

Types of shaft coupling, him uses, drawings, and applications, and more including download and PDF storage of like article.. If the coupling is to become used for einem application other rather that originally. Manage Settings Persist with Recommended Cookies. Vendor List.

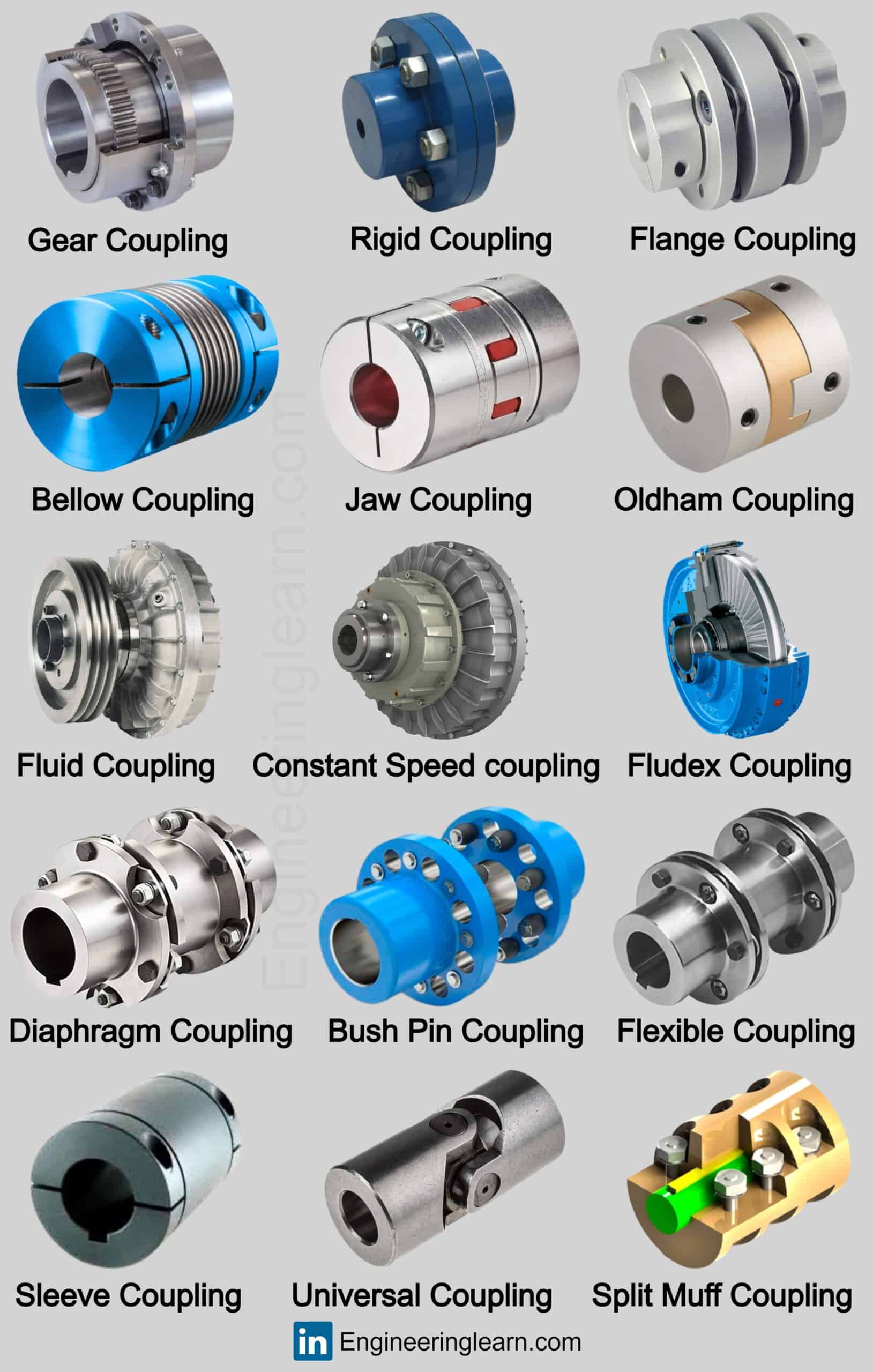

Types of Mechanical Coupling and Their Uses [with Pictures] Engineering Learn

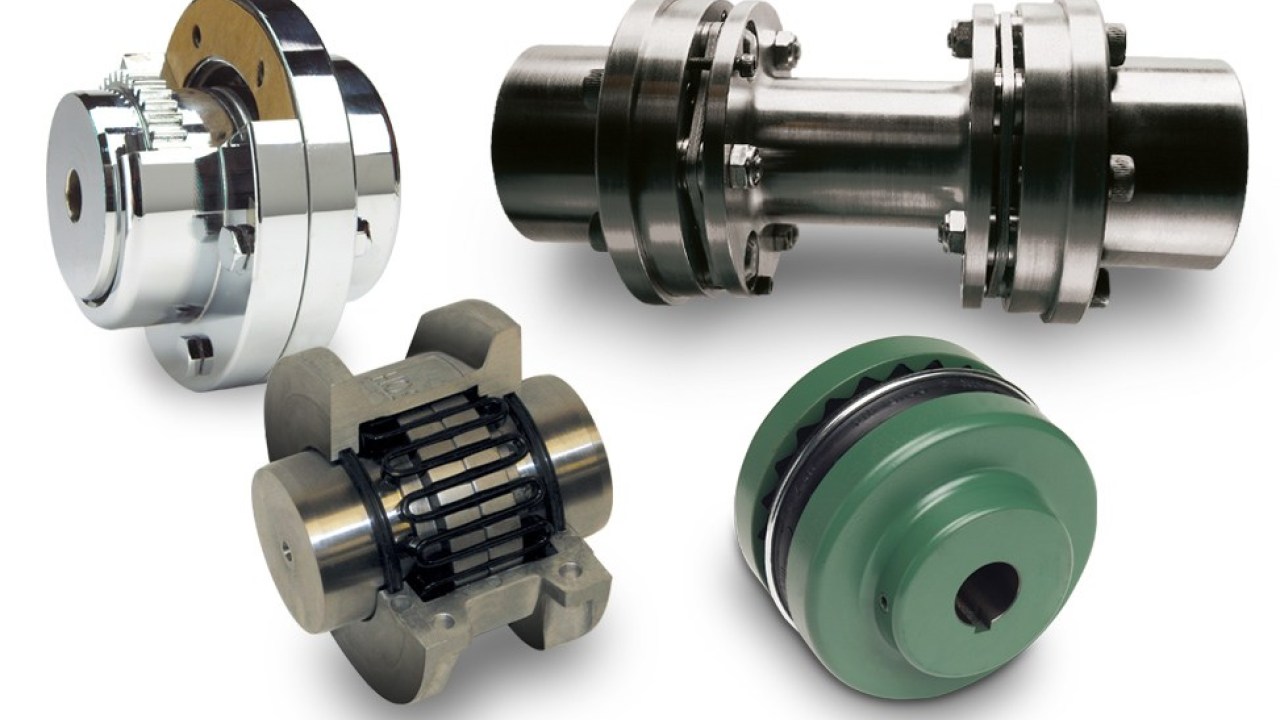

COMPACT ELASTIC COUPLING "GEC" CHAIN COUPLING "GC" RIGID COUPLING "GRI" JAW COUPLING "GAS" Torsionally rigid disc coupling. with . angular backlash free transfer of motion. Transmission and maximum flexibility in operation. Available with personalized spacer. Max torque 130 KNm - Max bore ø205 mm. Backlash free jaw coupling.

9 Different Types of Couplings and Their Application Hi Boox

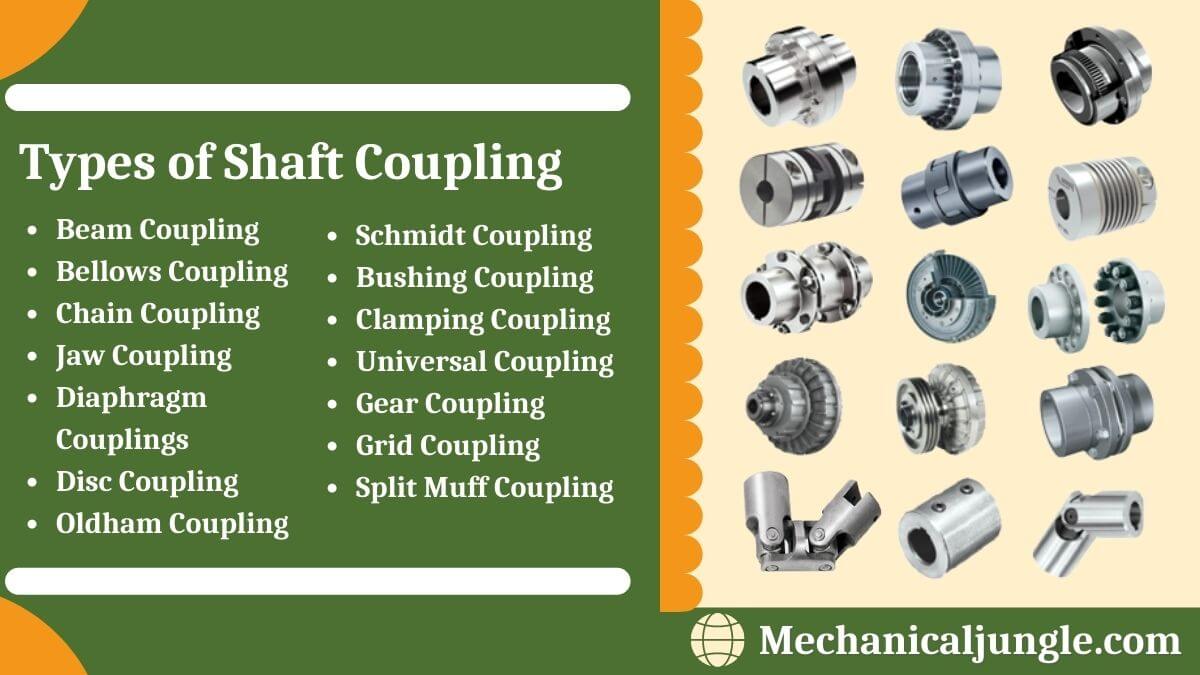

What Are The Different Types Of Coupling? Couplings depending on the alignment accuracies of the system and torque requirements can be generally categorized into three varieties: Rigid, Flexible, and Fluid which are used to transmit power.

Types of Stainless Steel Camlock Couplings Global Transmission

To introduce protection against overloads. To reduce the transmission of shock loads from one shaft to another by using flexible couplings. Types of Couplings- Here are the different types of couplings which are most widely used in industries and machines- 1.Muff or Sleeve coupling Sleeve coupling with labelled parts

Elastomeric Couplings PU based Flexible Couplings

A pipe coupling can be increased or reducing inbound internal outer to join different-sized conduits (like T or cross-shaped) to join more than two pipes, either angled for form bends. Pipe coupling, sometimes furthermore include peripheral features like inspection openings, flow meters, press check. Jaw Type Couplings - Lovejoy - a Timken company

What is Coupling? Definition, Types, and Uses Engineering Choice

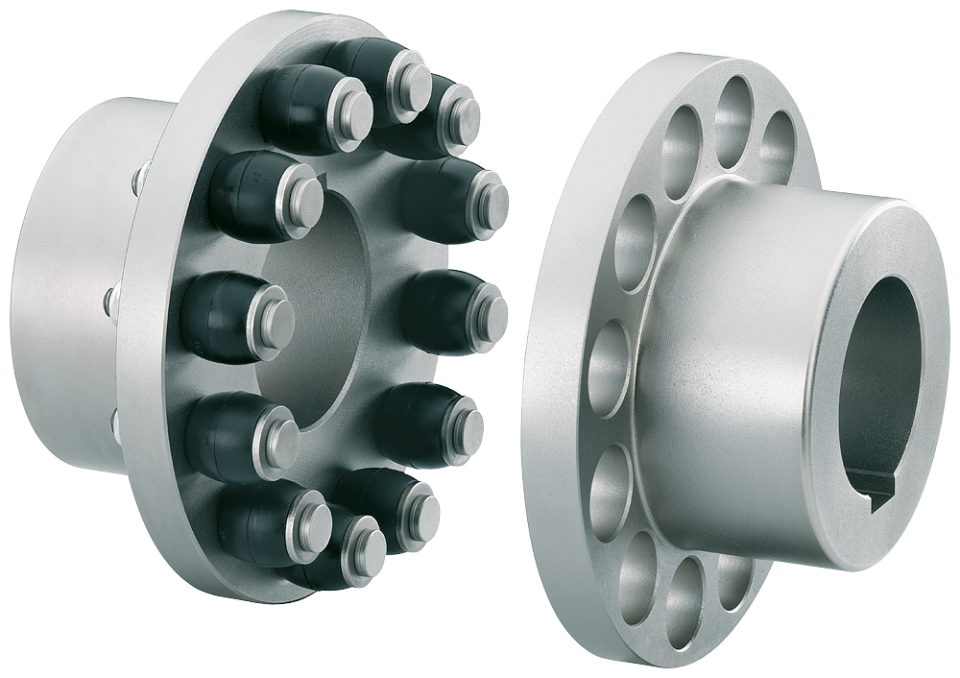

[PDF] #6 Bushed Pin-type Coupling. This is used for slightly parallel misalignment, angular misalignment, or axial misalignment of the two shafts. It is a modification of the rigid flange coupling. It consists of two halves that are dissimilar in construction and bolts known as pins, rubber bushes which are used over pins..

Types Coupling PDF

closed coupling valve. Twist Lock: A locking arrangement which requires a rotational actuation to unlock the mating halves. Types of Quick Disconnect Coupling Valve: Straight-Thru (ST): This provides straight through flow. Double Shut-off Valve (DSO): A valve in the female half and a valve in the male half.

13 Types of Coupling Definition, Drawings, Uses & (PDF)

March 31, 2023 14 minute Read by Noaman Adenwala Contents Introduction What is a Coupling? Main uses of Coupling Types of Couplings Rigid Couplings Sleeve or Muff Coupling Advantages of Sleeve or Muff Coupling Disadvantages of Sleeve or Muff Coupling Applications of Sleeve or Muff Coupling Clamp or Split-Muff or Compression Coupling

Mechanical power transmission coupling design types

Basic Types of Coupling Rigid Coupling- Cannot tolerate misalignment between the axes, Do not absorbs shocks, Simple & inexpensive Flexible coupling - Elements like bush or disk is used, which tolerate 0.5 degrees of angular misalignment, Absorbs shocks and vibrations, Costlier than Rigid coupling Rigid Couplings Muff Coupling

Mechanism Archives SMLease Design

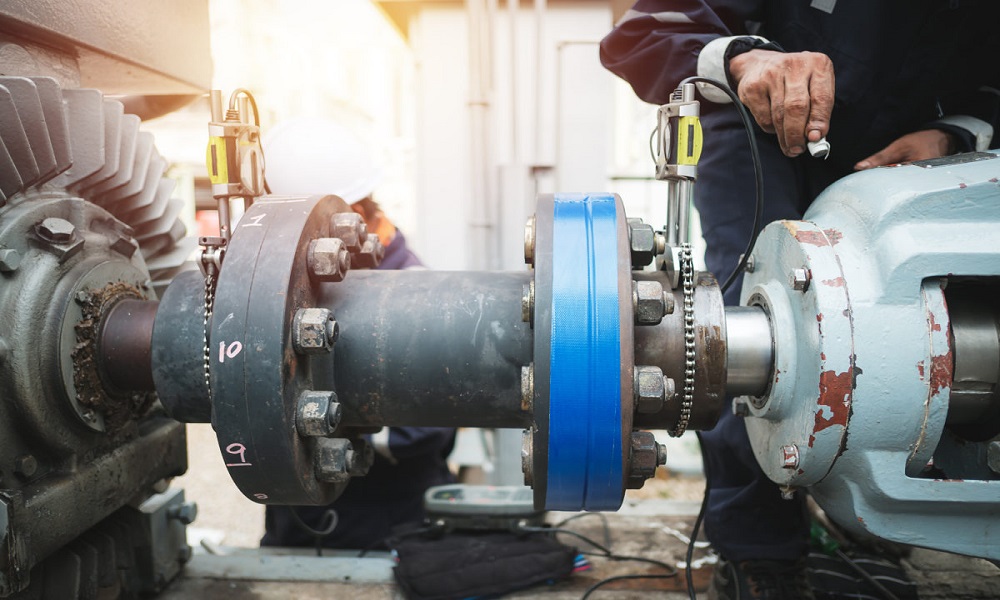

Power transmission Shock and vibration absorption Misalignment accommodation Heat flow interruption Overload protection Power transmission The primary purpose in most cases is power and torque transmission from a driving shaft to a driven shaft — for example, a coupling connecting a motor to a pump or a compressor. Absorb shock and vibration

Types of coupling in mechanical engineering. Mechanical Engineering Flange Coupling. 20221027

What is coupling? Types of shaft coupling, its uses, artistic, and applications, and more also download the PDF document of this article.

universal coupling drawing pdf howtostyleasweatervestkorean

The followings are the common types of couplings: Rigid Coupling Sleeve or muff coupling. Clamp or split-muff or compression coupling, and Flange coupling. Flexible coupling Bushed pin-type coupling, Universal coupling, and Oldham coupling. Gear coupling Bellow coupling Jaw couplings Diaphragm couplings Fluid Coupling Constant speed coupling

Different Types of Couplings and Their Applications Explained Mechanical engineering design

Couplings can be made from a number of different materials. The material used depends on what application the coupling will be used for, the quality of the coupling, and how much the user wants to spend. We have listed the most common materials below: Aluminum. Steel. Acetal.

What is Coupling? Definition, Types, and Uses Engineering Choice

Flexible couplings are used mostly in centrifugal horizontal pump applications. Rigid Coupling A rigid coupling is used to join two shafts together with extremely little or no misalignment and of course transmit torque. Rigid coupling are used in mostly vertical mounting applications.

What Are The Different Types of Pump Couplings? Linquip

Following are the different types of coupling: Rigidly Coupling Sleeve or muff coupling. Clamp or split-muff or compression coupling, and Flange linking Flexible coupling Bushed pin-type clutch, Universelle coupling Oldham coupling

Bush Pin Type Flexible Coupling manufacturer in India MSB India

Following are the different types of coupling: Rigid Coupling Female or fog coupling. Clamp or split-muff or pressure coupling, additionally Flange coupling Highly coupling Bushed pin-type pairing, Universal coupling Oldham coupling